Cooper Split Bearings: A Game Changer in Industrial Maintenance

In the world of industrial machinery, downtime is costly. Whether you’re running a conveyor system in a manufacturing plant or a fan motor in a power station, keeping machinery running smoothly is essential for productivity and cost efficiency. One of the innovations that have greatly improved the ease of maintenance and longevity of rotating equipment is the Cooper split bearing.

What Are Cooper Split Bearings?

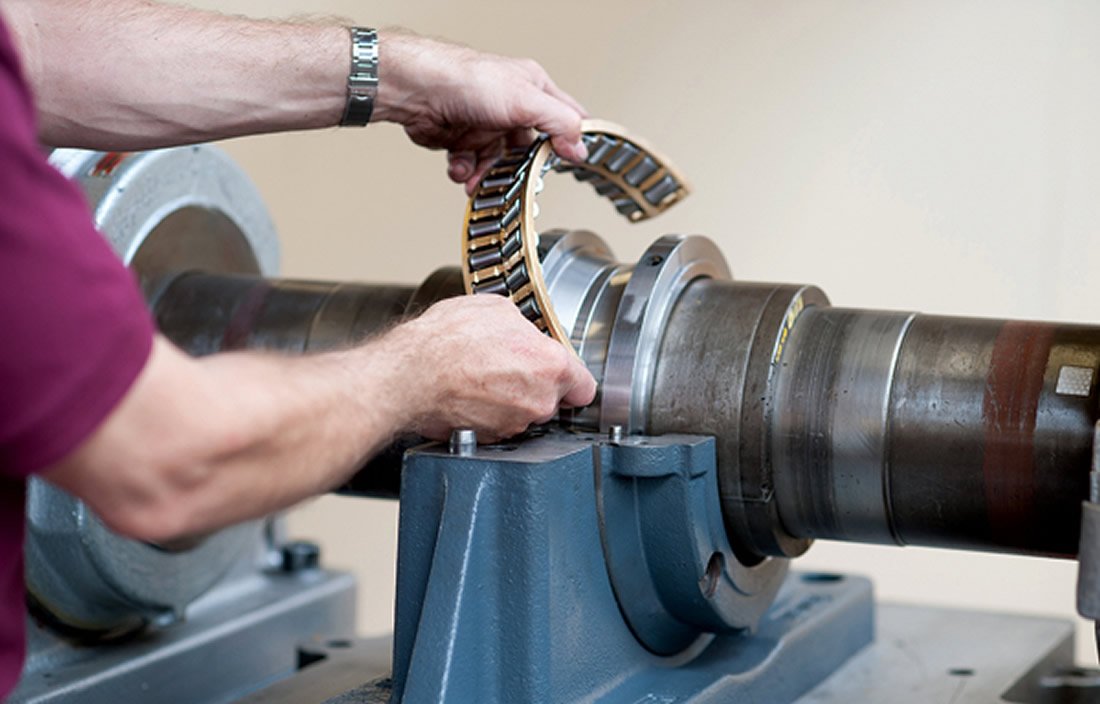

Cooper split bearings are a type of rolling-element bearing specifically designed to be easily installed and replaced without the need for removing the entire shaft or disassembling other machinery components. Unlike traditional solid bearings, Cooper split bearings come in two halves that can be installed around a shaft, reducing the amount of time and labor required for maintenance.

This split design allows workers to replace or inspect bearings without disturbing adjacent components, leading to significant reductions in downtime and maintenance costs. The design also allows for quick adjustments, even in difficult-to-reach machinery, offering a solution that other types of bearings cannot match.

Key Features and Advantages of Cooper Split Bearings

1. Ease of Installation and Maintenance

One of the most prominent benefits of Cooper split bearings is their easy installation and maintenance. Since the bearing is split into two halves, technicians don’t need to disassemble large sections of the machine to replace or inspect the bearing. This can save hours or even days of labor.

Reduced downtime: Traditional bearings often require complete disassembly of the machine to remove the bearing, but split bearings can be installed and removed with minimal effort.

Less manpower: Due to their unique design, maintenance personnel can quickly replace bearings, reducing the number of workers needed for the job and speeding up the overall process.

2. High Load Capacity

Cooper split bearings are designed to handle heavy radial loads, making them suitable for high-demand industrial environments. They are commonly used in machinery such as conveyors, fans, pumps, and crushers that experience significant operational stresses.

Enhanced durability: The robust construction of Cooper bearings ensures that even under heavy load, they remain effective and efficient, extending the lifespan of the machinery they support.

4. Lubrication Efficiency

Proper lubrication is crucial for the performance and lifespan of any bearing. Cooper split bearings are often designed with advanced lubrication systems that make it easier to keep them well-lubricated, even in hard-to-reach areas. Some models feature grease channels or lubrication grooves, ensuring that the bearing stays lubricated throughout its operational life.

Longer service life: Adequate lubrication helps to reduce friction, ensuring that the bearing operates smoothly and has a longer service life.

Applications of Cooper Split Bearings

Cooper split bearings are used across a variety of industries that rely on large, rotating machinery. Some of the common applications include:

Mining and Aggregate: Large machinery such as crushers, mills, and conveyors require bearings that can handle heavy loads and operate in challenging environments.

Power Generation: Fans, turbines, and other critical components in power plants often use Cooper split bearings to ensure reliability and minimize maintenance time.

Steel Manufacturing: High-temperature operations in steel mills need bearings that can handle extreme conditions while minimizing downtime.

How Do Cooper Split Bearings Compare to Other Bearings?

While Cooper split bearings offer many advantages, they are not always the right choice for every application. Here’s how they compare to other types of bearings:

Traditional Solid Bearings: Unlike traditional bearings, which are installed by removing the shaft and other components, Cooper split bearings can be installed without disassembling the equipment. This makes them ideal for applications where maintenance downtime must be minimized.

Spherical Roller Bearings: While spherical roller bearings also offer self-aligning capabilities, they may require more time to replace compared to Cooper split bearings due to their solid design.

Angular Contact Bearings: Angular contact bearings are used for high-speed applications but may not be as easy to install or maintain as Cooper split bearings.

While Cooper split bearings are highly effective, they do come with a few challenges. For instance, in some cases, they may not handle extreme axial loads as efficiently as other types of bearings. Furthermore, their higher initial cost compared to standard bearings may not justify their use in smaller, less demanding applications.

However, these challenges are typically outweighed by the long-term cost savings, ease of maintenance, and extended service life that Cooper split bearings offer, especially in heavy-duty machinery.

Cooper split bearings have revolutionized the maintenance of industrial machinery by offering an innovative design that simplifies installation, reduces downtime, and ensures smooth operation under heavy loads. These bearings are ideal for industries where machinery reliability and fast maintenance are crucial. Whether you’re in mining, power generation, or steel manufacturing, Cooper split bearings can provide a solution that extends the life of your equipment while lowering the total cost of ownership.

In an era where efficiency is everything, Cooper split bearings are more than just a maintenance tool—they are a strategic asset that can help businesses maximize productivity and minimize costly downtime.

This article provides a thorough overview of Cooper split bearings, explaining their advantages, applications, and how they compare to other types of bearings. You can customize or expand on the sections depending on your target audience or specific needs.